MEP Expert

MEP expert

Saturday, 26 September 2015

Material Activity flow diagram.

The main concept of develop the activity flow diagram to highlight the sequence of MEP activities installation in multistory buildings and towers. This flow diagram is very useful while preparing construction shedule.

The activity flow diagram deals only to get the idea overall system. For more detail , MEP interface with civil activity and production rate refer the relevant section.

The flow diagram includes all drawing and material submittal and approval as well as material procurement and delivery sequence.

ELECTRICAL ACTIVITY FLOW DIAGRAM

HVAC ACTIVITY FLOW DIAGRAM

PLUMBING ACTIVITY FLOW DIAGRAM

FIRE FIGHTING ACTIVITY FLOW DIAGRAM

Monday, 21 September 2015

Different levels involved in MEP

Good Morning :-)

The MEP works cover over 40% of the total construction cost and so the care should be more in every execution steps.

In general the overall MEP works can be categorized into different steps. By having a knowledge on this A MEP engineer

can do proper planning of Time, Resource, Cost etc ;

A MEP fresher should have a copy of this with him, which could be helpfull for a better project execution.

The MEP works cover over 40% of the total construction cost and so the care should be more in every execution steps.

In general the overall MEP works can be categorized into different steps. By having a knowledge on this A MEP engineer

can do proper planning of Time, Resource, Cost etc ;

A MEP fresher should have a copy of this with him, which could be helpfull for a better project execution.

Sunday, 20 September 2015

What is MEP ?

Good Morning :-)

Today Morning I was amazed to see the number of viewers of my blog, thanks for those cool guys.

So I thought of sharing something really useful( MEP beginners) .

The works in MEP is mainly divided into Mechanical, Electrical and Plumbing.

Mechanical

The mechanical installation mainly cover HVAC works.

Electrical

The Electrical installation is covering all installation works, fire alarm system, telephone system, telephone system, BMS, low voltage system.

Plumbing

The Plumbing installations is covering drainage system, water supply distributions, sanitory ware installations and related works.

Fire Fighting System

The fire fighting system is covering sprinkler system, fire fighting equipments, clean agent, FM200 system, etc

Today Morning I was amazed to see the number of viewers of my blog, thanks for those cool guys.

So I thought of sharing something really useful( MEP beginners) .

The works in MEP is mainly divided into Mechanical, Electrical and Plumbing.

Mechanical

The mechanical installation mainly cover HVAC works.

Electrical

The Electrical installation is covering all installation works, fire alarm system, telephone system, telephone system, BMS, low voltage system.

Plumbing

The Plumbing installations is covering drainage system, water supply distributions, sanitory ware installations and related works.

Fire Fighting System

The fire fighting system is covering sprinkler system, fire fighting equipments, clean agent, FM200 system, etc

Thursday, 17 September 2015

Good Evening :-)

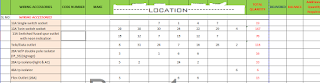

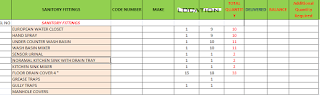

It was yet another day with hectic shedule. Today I want to share something that I came across yesterday, I am sure you people might be having a much better mode of execution. Its about the material tracking, last day I had a visit in our material store I could find that even the store keeper is not having an apt idea about the material availability,this should be solved because in a fastrack project like ours, the availabilty of material is very crucial. So I thougt of making some tracking records, which could reflect positively in my work shedule.

It was yet another day with hectic shedule. Today I want to share something that I came across yesterday, I am sure you people might be having a much better mode of execution. Its about the material tracking, last day I had a visit in our material store I could find that even the store keeper is not having an apt idea about the material availability,this should be solved because in a fastrack project like ours, the availabilty of material is very crucial. So I thougt of making some tracking records, which could reflect positively in my work shedule.

Wednesday, 16 September 2015

Good Morning :-)

Its hardly 2 months I have been here in Dubai as MEP Engineer. Even if I have an experience of 3+ years in MEP , here I encounter a totally different scenario of work. The DEWA has internationally best set of regulations, which makes the Dubai MEP works in its pinnacle.

Here I could find most of the works are fastrack projects. This gives the Engineers a lack of time for proper planning, where most of the companies approach a third party for its planning activities. This could not be possible for most of the small and medium level companies. Mine is a similar type of company and here too the coordination between different departments are lagging.

Here I am indulged in a multi million project, one of the largest project I had worked with.

Here some preliminary jobs are in progress ,like... keeping sleeves, allotting gaps (filling thermocols inside steel before concreting) that could be used in future.

Allotting manholes is also an important job

In these stage 0(what I call) activities there are a lot of things which we have to taken care of

1) Planning

- It can be done by studying the drawings thoroughly(if you are not good in CAD drawings ask for the help of draftman).

- Finding the shortest and the safest way for the execution(should be approved by the consultant).

2) Alloting some extra sleeves(or future provision)

3) Paper works- keep an updated record of daily activities (recommended in excel)

Stage 1- where we have to do the

Conduit execution, for the light and power...etc (Electrical and other LV works)

Fixing the drainage system,fixing pipes for WC,Urinal,Floor drains,Clear out, pipes for Wash Basin.. etc (Plumping works)

Fixing pipes for AC drains,pipes for copper wires etc (Mechanical works)

Its hardly 2 months I have been here in Dubai as MEP Engineer. Even if I have an experience of 3+ years in MEP , here I encounter a totally different scenario of work. The DEWA has internationally best set of regulations, which makes the Dubai MEP works in its pinnacle.

Here I could find most of the works are fastrack projects. This gives the Engineers a lack of time for proper planning, where most of the companies approach a third party for its planning activities. This could not be possible for most of the small and medium level companies. Mine is a similar type of company and here too the coordination between different departments are lagging.

Here I am indulged in a multi million project, one of the largest project I had worked with.

Here some preliminary jobs are in progress ,like... keeping sleeves, allotting gaps (filling thermocols inside steel before concreting) that could be used in future.

Allotting manholes is also an important job

In these stage 0(what I call) activities there are a lot of things which we have to taken care of

1) Planning

- It can be done by studying the drawings thoroughly(if you are not good in CAD drawings ask for the help of draftman).

- Finding the shortest and the safest way for the execution(should be approved by the consultant).

2) Alloting some extra sleeves(or future provision)

3) Paper works- keep an updated record of daily activities (recommended in excel)

Stage 1- where we have to do the

Conduit execution, for the light and power...etc (Electrical and other LV works)

Fixing the drainage system,fixing pipes for WC,Urinal,Floor drains,Clear out, pipes for Wash Basin.. etc (Plumping works)

Fixing pipes for AC drains,pipes for copper wires etc (Mechanical works)

Tuesday, 15 September 2015

This blog is created to initiate the discussion and experience sharing between MEP professionals to

help each other and develop new construction sub industry. (y)

Labels:

Construction,

Electrical,

Mechanical,

MEP,

MEP UAE,

Plumping

Subscribe to:

Comments (Atom)